Obtaining of fire-resistant materials by self-propagating high-temperature synthesis

Principle investigators:

1. Radishevskaya Nina Ivanovna, Senior Researcher, PhD (osm.ninaradi@yandex.ru).

2. Lepakova Olga Klavdievna, Senior Researcher, Ph.D (Klavdievna.K@yandex.ru).

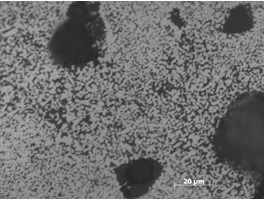

Self-propagating high-temperature synthesis (SHS) can be used to develop new technologies for the production of refractory non-metallic composites with desired properties. A fire-resistant material on the basis of titanium diboride with addition of chemically resistant magnesium aluminate spinel with refractory properties was first obtained using SHS method. The obtained material is TiB2-MgAl2O4 composite, in which TiB2 particles with size not exceeding 5 microns are uniformly distributed in the matrix of magnesium aluminate spinel. The formed surface layer of MgAl2O4 at the grain boundary of TiB2 prevents the growth of TiB2 crystals and provides a fine-grained structure of the composite. High temperatures of titanium diboride synthesis (~3000 °C) contribute to melting of magnesium aluminate spinel (Tmelt=2135 °C), which, spreading over the surface of titanium diboride grains, forms a matrix that protects the surface of TiB2 grains by spinel, which makes it possible for the composite to work in corrosive oxidizing media (Fig. 1).

Microstructure of SHS-composites based on titanium diboride with addition of MgAl2O4: 75%(Ti+2B) + 25% MgAl2O4.

This composite can be used as a fire-resistant insulating material that can operate in high-temperature oxidizing environments.