Ultrahard ceramic powder - Aluminum Magnesium Boride AlMgB14 ("slippery ceramics")

Principle investigators:

1. Olga Klavdievna Lepakova, Senior Researcher, Ph.D (Klavdievna.K@yandex.ru).

2. Boris Shulevich Braverman, Senior Researcher, Ph.D (bbraverman@yandex.ru).

Ultrahard ceramic powder ("slippery ceramics") - Aluminum Magnesium Boride AlMgB14 was obtained. Boron-magnesium-aluminum alloy is characterized by high hardness ~ 32 GPa and a very low friction coefficient ~ 0.02. For example, for teflon the friction coefficient is from 0.04 to 0.1 and 0.16 for well lubricated steel. Ceramic powder based on AlMgB14 has high resistance to abrasion and erosion and high chemical inertness and thermal resistance.

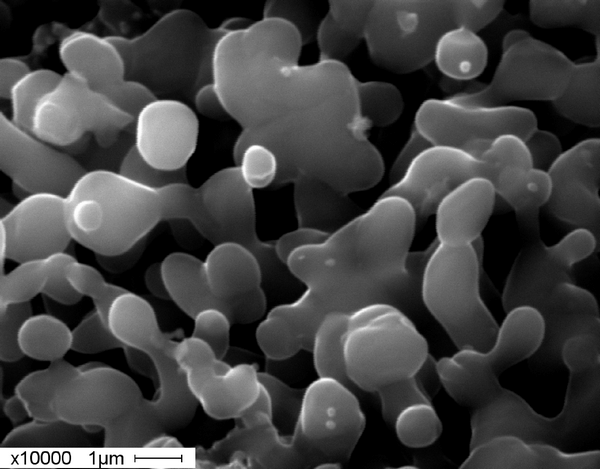

Microstructure of SHS-aluminum magnesium boride (AlMgB14).

Possible use:

This material can be used as an anti-wear composite additive and as a raw material for lubricating and wear-resistant coatings operating under extreme conditions. Coatings based on AlMgB14 can be widely used for all friction elements such as bearings, pump shafts, turbines, cutting tools, drills, etc. In addition, these coatings can be widely used in military engineering, such as in the manufacture of bearings and shafts for submarines to significantly reduce noise. Also the developed material, due to its low density and high hardness, can find practical application as armor protection material.

Possible implementation:

These ultrahard low-friction materials will significantly save energy and reduce noise from equipment, such as turbines and pumps.

Readiness for use:

The samples of ultrahard ceramic powder AlMgB14 were obtained under laboratory conditions.

Comparison with known developments:

At the moment, almost no one in Russia is engaged in applying a composition based on AlMgB14, since this direction is new. In addition, the physical and mechanical properties of obtained AlMgB14 are higher than the those of existing analogues, such as aluminum oxide and zirconium dioxide, and the cost is lower. The data obtained by the American laboratory Ames (Department of Energy Ames laboratory, USA) showed that AlMgB14 is inferior in hardness only to diamond and boron nitride and has a unique coefficient of friction.

Patentability:

RF patent No. 2697146. A method for obtaining an ultrahard ceramic powder AlMgB14. Lepakova O.K., Braverman B.Sh., Afanasyev N.I., Golobokov N.N. Application 2018138211, 29.10.2018. Publ. 08/12/2019 Bul. No. 23.